Continued from Electric bike build part 2.

I now had all the parts and tools available to fit the motor to the BB shell. I had read that the high torque from the motor could dent alloy frames so I picked up some Neoprene rubber to try and reduce the chance of this happening:

Rubber applied:

Test fit, the final fit will have the rubber fully compressed between the motor and frame:

Looks good!

One slight issue I had was the hole on this steel bracket being drilled slightly offset, meaning the fastener wasn't able to be fitted without binding. I drilled the hole 0.5mm larger then nail polished the exposed metal:

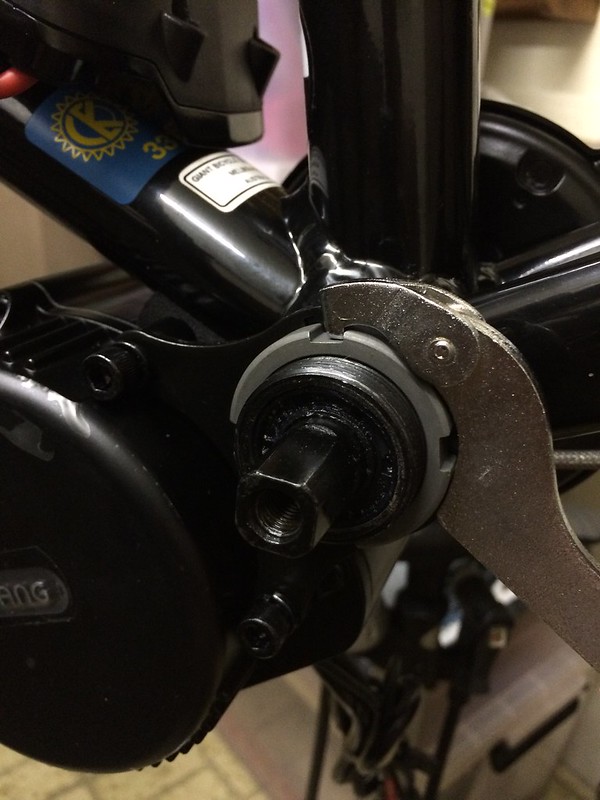

Thanks yet again to my Aldi bike toolkit I had the right tool on hand. I was able to (blue) Loctite then tighten at the same time as holding the motor against the frame fully compressing the rubber:

All done:

I then applied Loctite to the two additional bolts and the extra lockring (you can use a standard Shimano Hollowtech II tool) then fitted:

Here's a pic after I fitted both crankarms and chain:

It's starting to come together!

Continued at Electric bike build part 4.

No comments:

Post a Comment